ICD/ITKE Research Pavilion 2016-17

%20ICD_ITKE.jpg)

Lightweight fiber composite materials have tremendous potential in architectural applications, as material self-weight is of high concern for larger span structures. However, we currently lack adequate fiber composite fabrication processes to produce at this scale without compromising the design freedom and system adaptability required for the architecture and design industries. Traditional methods of fabrication require full-scale surface molds and often restrict the process to serialized production of identical parts. Previous research at the Institute for Computational Design & Construction (ICD) and Institute for Building Structures and Structural Design (ITKE) has explored fibre composite construction without the need for surface moulds or costly formwork. These novel manufacturing processes have been utilized to create highly differentiated multi-layered structures, functionally integrated building systems and large element assemblies. However, the scale of these early investigations has been limited by the working space of the industrial robotic arms that were utilized. The goal of the ICD/ITKE Research Pavilion 2016-17 was to envision a scalable fabrication process and to test alternative scenarios for architectural application by developing a manufacturing process for long span continuous fibre structures.

For this project, I was particularly responsible for characterization of the fiber composites, biomimetics research, construction detailing, and I was heavily involved in fabrication.

Full project team can be found below

Creating a long span structure, beyond the working space of standard industrial fabrication equipment, required a collaborative setup where multiple robotic systems could interface and communicate to create a seamless fibre laying process. A fibre could be passed between multiple machines to ensure a continuous material structure. The concept of the fabrication process was based on the collaboration between strong and precise, yet stationary machines with limited reach and mobile, long-range machines with limited precision. In the specific experimental set-up, two stationary industrial robotic arms with the strength and precision necessary for fibre winding work were placed at the extremities of the structure, while an autonomous, long range but less precise fibre transportation system was utilized to pass the fibre from one side to the other, in this case a custom-built UAV. Combining the untethered freedom and adaptability of the UAV with the robots, opened up the possibilities for laying fibres on, around or through a structure, creating the potential for material arrangements and structural performance not feasible with the robot or UAV alone.

Fabrication scenario for the ICD/ITKE Research Pavilion 2016-17

One focus of the project was a parallel bottom-up design strategy for the biomimetic investigation of natural construction processes of long span fibre composite structures and the development of novel robotic fabrication methods for fibre reinforced polymer structures. The aim was to develop a fibre winding technique over a longer span, which reduces the required formwork to a minimum whilst taking advantage of the structural performance of continuous filament. Therefore, functional principles and construction logics of natural lightweight structures were analysed and abstracted in cooperation with the Institute of Evolution and Ecology and the department for Paleobiology of the University of Tübingen. Two species of leaf miner moths, the Lyonetia clerkella and the Leucoptera erythrinella, whose larvae spin silk “hammocks” stretching between connection points on a bent leaf, were identified as particularly promising for the transfer of morphological and procedural principles for long span fibrous construction. Several concepts were abstracted from the biological role models and transferred into fabrication and structural concepts, including: the combination of a bending-active substructure and coreless wound fibre reinforcement to create an integrated composite winding frame, fibre orientation and hierarchy over a long span structure and multi-stage volumetric fibre laying processes for the generation of complex three dimensional geometries.

%20(1).jpg)

Bending Frame with

Fiber Reinforcement

Fiber Orientations & Hierarchy

Edge Reinforcement

Volumetric

Multi-Stage Winding

Biomimetic investigation with Lyonetia clerkella (top left) and Leucoptera erythrinella (top right) as fiber construction role models

An adaptive control and communication system was developed to allow multiple industrial robots and a UAV to interact throughout the winding and fibre laying processes. An integrated sensor interface enabled the robots and UAV to adapt their behaviours, in real time, to the changing conditions during fabrication. The UAV could fly and land autonomously without the need of human pilots, the tension of the fibre was actively and adaptively controlled in response to both the UAV and robot behaviours. A localization system was utilized to create a digital and physical “handshake” between the robot and the UAV in order to pass the fibre back and forth throughout the winding process. The series of adaptive behaviours and integrated sensors lay the foundation for developing novel multi-machine, cyber-physical fabrication processes for large scale fibre composite production.

Communication setup for pavilion fabrication

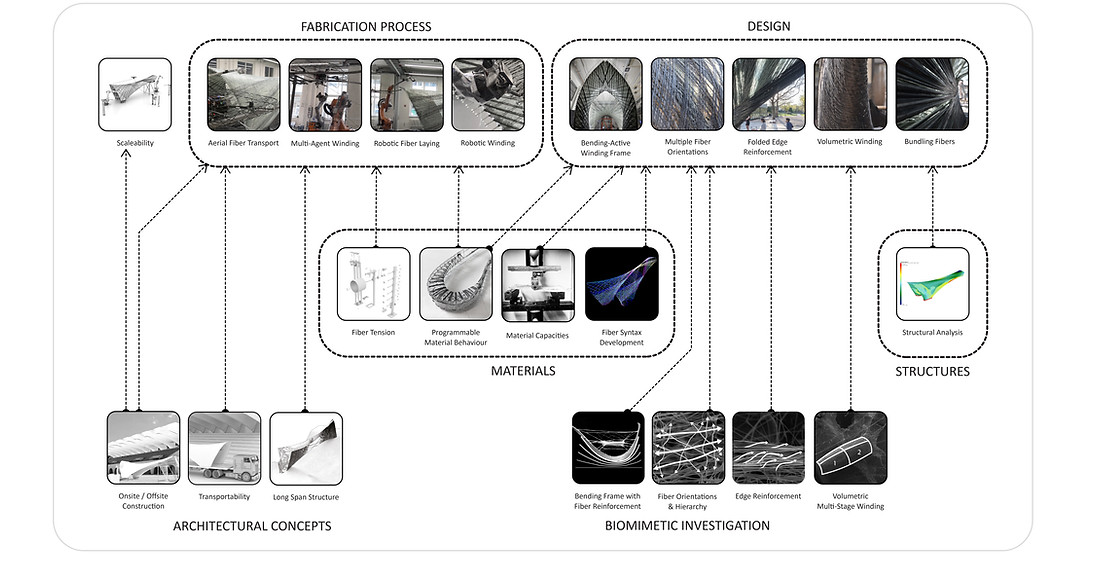

This research showcases the potential of computational design and construction through the incorporation of structural capacities, material behaviour, fabrication logics, biological principles and architectural design constraints into integrative computational design and construction.

Integrative design space

The ICD/ITKE Research Pavilion 2016-17 was created by laying a combined total of 184 km of resin-impregnated glass and carbon fibre. The lightweight material system was employed to create and test a single long spanning cantilever with an overall length of 12 m as an extreme structural scenario. The surface covers an area of about 40 m² and weighs roughly 1000 Kg. The pavilion’s overall geometry demonstrates the possibilities for fabricating structural morphologies through multi-stage volumetric fibre winding, reducing unnecessary formwork through an integrated bending-active composite frame, and increasing the possible scale and span of construction through integrating robotic and autonomous lightweight UAV fabrication processes.

%20ICD_ITKE.jpg)

%20ICD_ITKE.jpg)

%20ICD_ITKE.jpg)

Pavilion installed onsite

Full project team details:

ICD Institute for Computational Design and Construction – Prof. Achim Menges

ITKE Institute of Building Structures and Structural Design – Prof. Jan Knippers

Scientific Development

Benjamin Felbrich, Nikolas Früh, Marshall Prado, Daniel Reist, Sam Saffarian, James Solly, Lauren Vasey

System Development, Fabrication and Construction

Miguel Aflalo, Bahar Al Bahar, Lotte Aldinger, Chris Arias, Léonard Balas, Jingcheng Chen, Federico Forestiero, Dominga Garufi, Pedro Giachini, Kyriaki Goti, Sachin Gupta, Olga Kalina, Shir Katz, Bruno Knychalla, Shamil Lallani, Patricio Lara, Ayoub Lharchi, Dongyuan Liu, Yencheng Lu, Georgia Margariti, Alexandre Mballa, Behrooz Tahanzadeh, Hans Jakob Wagner, Benedikt Wannemacher, Nikolaos Xenos, Andre Zolnerkevic, Paula Baptista, Kevin Croneigh, Tatsunori Shibuya, Nicoló Temperi, Manon Uhlen, Li Wenhan. With the support of Michael Preisack and Artyom Maxim.

In collaboration with:

Institute of Aircraft Design (IFB) – Prof. Dr.-Ing. P. Middendorf, Markus Blandl, Florian Gnädinger

Institute of Engineering Geodesy (IIGS) – Prof. Dr.-Ing. habil. Volker Schwieger, Otto Lerke

Department of Evolutionary Biology of Invertebrates, University of Tuebingen – Prof. Oliver Betz

Department of Palaeontology of Invertebrates, University of Tuebingen – Prof. James Nebelsick

Supported by

Volkswagen Stiftung

GETTYLAB

Kuka Roboter GmbH

Peri GmbH

SGL Technologies GmbH

Hexion Stuttgart GmbH

Ed. Züblin AG

Lange Ritter GmbH

Stahlbau Wendeler GmbH

Leica Geosystems GmbH

KOFI GmbH

Researchers on this project have received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodoska-Curie grant agreement No 642877, from the Collaborative Research Centre CRC 141 of the German Research Foundation and from the Volkswagen Stiftung’s Experiment! funding programme.

-01.jpg)